Rejuvenated textile waste for a circular world

Textile waste is reaching unimaginable levels. It is one of the largest polluters in the world with more than 13 million tons of textile waste thrown away worldwide each year.

Every second, one truck of textile waste is burned or landfilled.

Together with Purfi, we found a way to reduce it: Pur-fill.

Developed by rejuvenating pre-consumer textile fibers, this upcycled insulation is the new frontier of sustainability.

Pur-fill, powered by Purfi, comes from textile waste, collected from all over the world.

Instead of letting textile waste go to waste, Purfi collects a variety of pre-consumer, post-industrial materials from partners.

Their collection facilities are located in textile dense areas worldwide to lower transportation and resource costs, and ultimately, environmental impact.

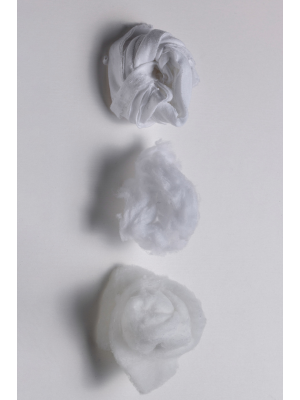

Pur-fill’s upcycling process. Three steps which can change the world:

- Collect both post-industrial and pre-consumer textile waste

- Rejuvenate fibers through Purfi’s patented process

- Create an upcycled, high-quality insulation

We’re proud to have partnered with Purfi. Through their technology, textile waste undergoes a rejuvenation process, transforming it into raw materials in response to the global waste challenge and contributing to the creation of valuable paddings.

Purfi & Imbotex together for a 360° approach to sustainability.